A crucial component of tunnel building is tunnel illumination. LED tunnel lights are currently the most popular option for tunnel illumination due to advancements in LED lighting technology. When choosing LED tunnel lights that are appropriate for engineering customers, the following safety measures should be taken: Which ones?LED Tunnel Light Buying Guide

In recent years, LED tunnel lights have become a common lighting fixture in road tunnels. It is highly well-liked due to its unique benefits. The following benefits make tunnel lights a well-liked option:

1. Light effect: Light efficiency is a critical element since it impacts operating energy costs. The majority of LED tunnel light producers have currently attained 100lm/W, which satisfies the tunnel lighting industry's requirements for light efficiency. However, it is advised to prioritize LED bulbs with higher light efficiency if you want to efficiently minimize electricity expenditures. With an LED tunnel light's luminous efficiency of up to 150lm/W, Shenzhen Aglare Lighting can save more money on electricity than other manufacturers.

2. Driving power supply: Unlike LED light sources, which have a service life of over 100,000 hours, driving power supplies have substantially shorter lifespans. Thus, the driving power supply—rather than the LED light source—determines the lifespan of the LED tunnel light. Selecting a high-quality driving power source is crucial to ensuring the service life of LED tunnel lights. Among the well-known brands of power supplies in the market are Hangzhou Infinite, Shenzhen Maoshuo, Taiwan MEAN WELL, etc.

3. Protection level and surface technology:Tunnel lights are used in outdoor environments. There is water seepage or dripping in the tunnel. The working environment is relatively harsh. In eastern coastal cities, the air contains high levels of salt spray, so the lamps should have a high IP protection level. The IP level is not lower than IP65. The surface It should be treated with special technology to prevent salt spray and have strong corrosion resistance.

4. Lamp heat dissipation: The LED light source's light attenuation is directly impacted by the lamp's heat dissipation effect. The lamp with superior heat dissipation performance has less light attenuation than the lamp with worse heat dissipation performance under the same circumstances. Consequently, you should aim to select aluminum lamp bodies, lamps with a suitable heat dissipation structure, and lamps with a broad heat dissipation surface when selecting LED tunnel lights.Glare in the Lighting Surface light sources are LED tunnel lights. When compared to traditional LED tunnel lights of the same power, the quantity of LED chips is significantly higher. Compared to standard LED tunnel lights, the corresponding single LED current is modest, the node temperature is low, the light source decay is short, and the lamp life is longer.

5. Protection against glare: The glare issue caused by lighting greatly impairs a driver's vision. One major factor in safety-related incidents is glare. As a result, you should consider the tunnel lights' ability to reduce glare when making an LED purchase. The LED tunnel lights from Aglare Lighting are powered by its proprietary film flat fluorescent LED light source (FLED), which produces flat light with a consistent, gentle light color, minimal glare, and effective anti-glare properties.

6. Color rendering index: The greater the color rendering index, the better it can match lighting needs and the clearer and brighter it is under the same light effect. For instance, typical tunnel sodium lamps have a low color rendering index, which makes the light appear dimmer even when their luminous flux is not low. The color rendering index of LED lighting is significantly higher than that of conventional sodium lighting. A color rendering index of at least 70 is generally considered adequate. Since tunnels are not intended for precise work, high CRI standards are not necessary.

7. Color temperature: The choice of color temperature should take into account the particulars of the tunnel. For instance, low color temperatures, such as 3000K for warm white light, should be used in mountainous areas where there is a lot of fog because they are more able to penetrate than high color temperatures; in tunnels without fog, such as urban underground passageways, etc., you can choose between 5500K and 6500K color temperatures because these have the highest luminous flux and good brightness; in general, you can choose between 4000 and 4500K color temperatures for natural white light and take both into consideration.

8. Factor of power

High-power lamps, like LED tunnel lights, typically require PF>0.9 due to the effect on the national grid load.

Now that you have an idea of choosing the proper tunnel lights for your needs, Let’s take a look at the best LED tunnel lighting.

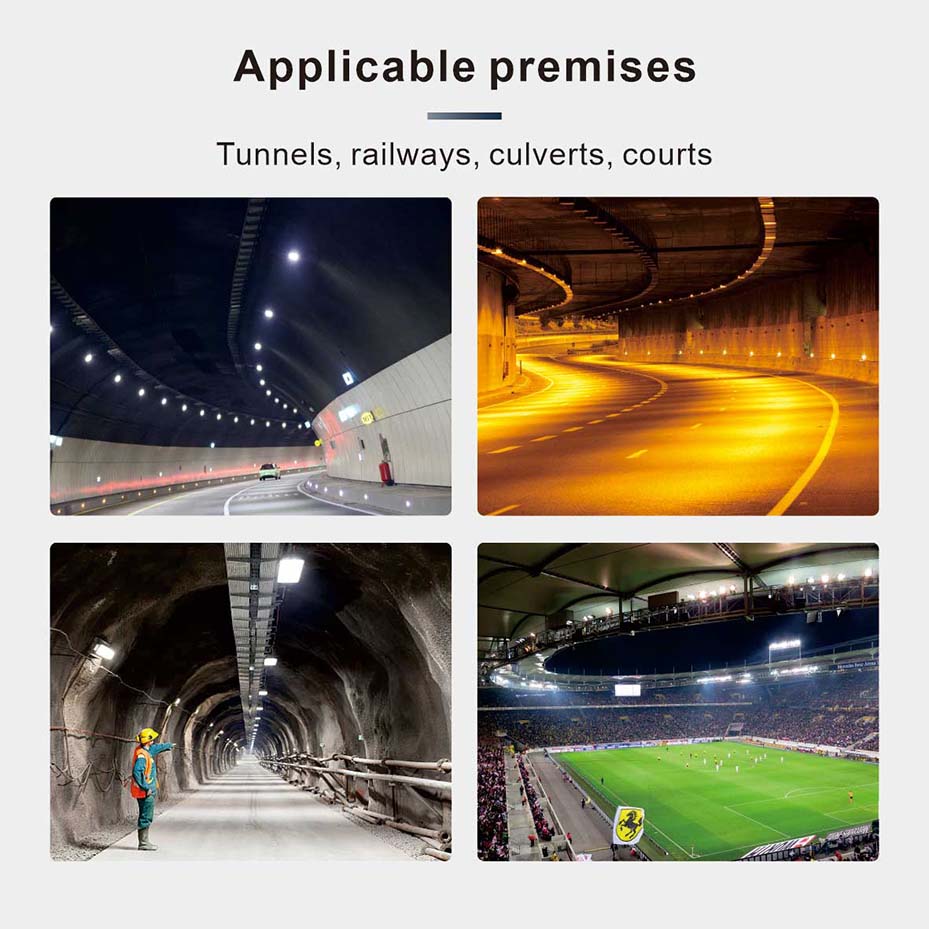

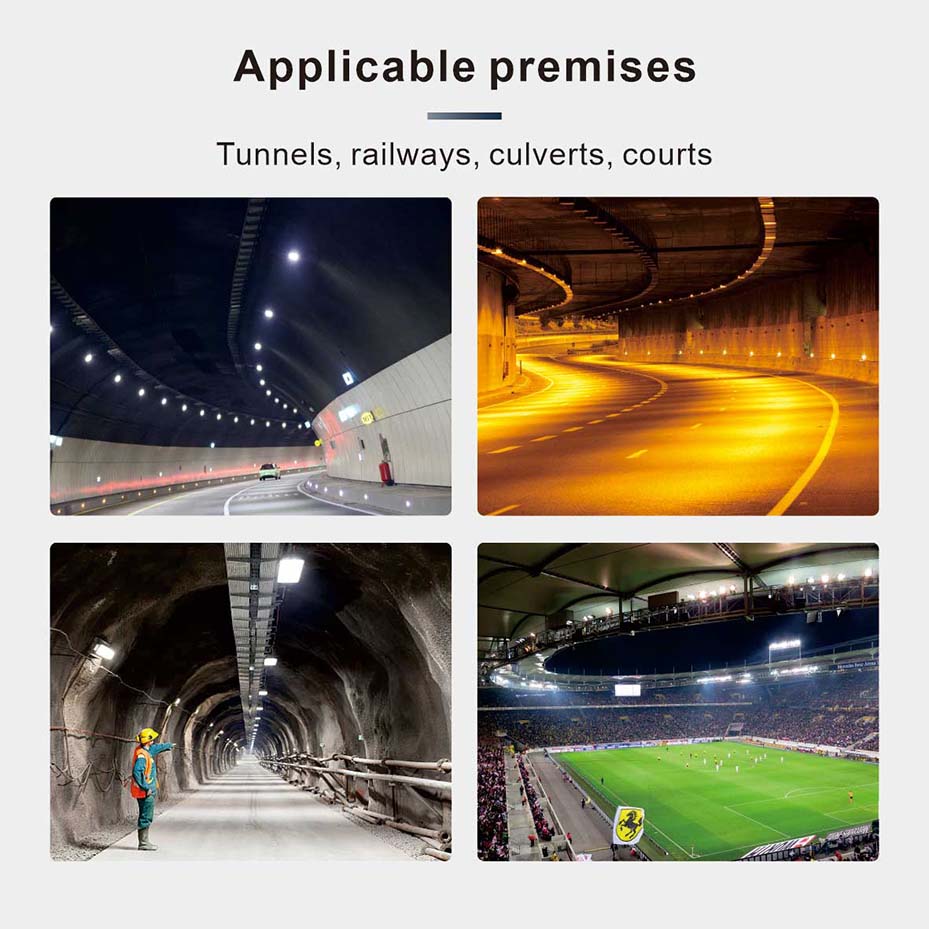

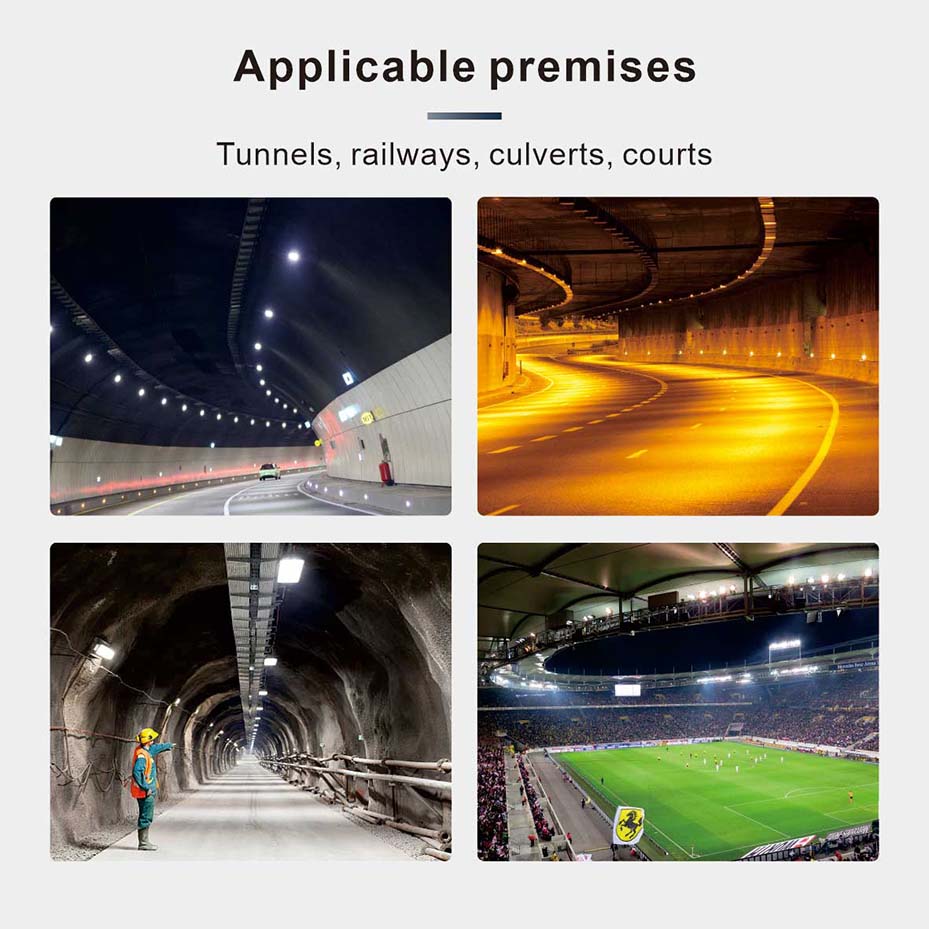

At Aglare Lighting, we are proud to be a leading manufacturer of high-power LED floodlights specifically designed for outdoor engineering lighting. One of our most popular products is the LED tunnel flood light, which has been carefully crafted and engineered to enhance visibility and ensure safety in tunnel and underpass areas for road and rail applications.

Our factory is capable of producing LED tunnel flood lights in a variety of wattages to accommodate different lighting requirements. Whether you need a 50W, 100W, 150W, 200W, 250W, 300W, 400W, or 500W lighting solution, we have you covered. With such a wide range of options available, you can select the perfect LED tunnel lights to suit your specific needs.